What waste can be refined with waste oil distillation device? How about their oil yield?

Waste oil distillation represent a critical technology in the management and recycling of various types of waste oils. These facilities transform waste oils into diesel used in heavy machinery, generator, boiler. This article explores the types of waste that can be processed in a waste oil distillation device and their respective oil yield.

Types of Waste Suitable for Distillation

1. Used Engine Oil: Engine oils that have been drained from vehicles, machinery, and industrial equipment can be refined. These oils often contain impurities due to wear debris, combustion byproducts, and additives.

2. Hydraulic Fluid: Waste hydraulic fluids from machinery and industrial processes can be processed. These fluids, which may contain additives and impurities from their use, can be purified for reuse.

3. Gear Oil: Gear oils from transmissions and mechanical systems can be refined. These oils often contain metal particles and other contaminants that are removed during the distillation process.

4. Coolant Fluids: Waste coolant fluids used in various industrial applications can be refined. These fluids often contain impurities from corrosion and other chemical reactions.

5. Industrial Process Oils: Oils used in various manufacturing processes, such as cutting oils, drawing oils, and metalworking fluids, can be recycled through distillation.

Oil Yield from Waste Oil Distillation

The oil yield from a waste oil distillation device varies depending on several factors, including the type of waste oil, the efficiency of the distillation process, and the quality of the initial waste material.

1. Used Engine Oil: Typically, distillation of used engine oil can yield around 70-80% of the original volume in the form of refined oil. The remaining material consists of impurities and solid residues.

2. Hydraulic Fluid: Yield rates for hydraulic fluids are similar, often ranging between 70-85%. The distillation process effectively removes water and other contaminants.

3. Gear Oil: Gear oils generally yield about 75-85% of refined oil. The distillation process is particularly effective in removing metal particles and other solid debris.

4. Coolant Fluids: The yield for coolant fluids is lower, typically around 50-60%, as these fluids often contain water and other additives that are not fully recoverable.

5. Industrial Process Oils: Yields for these oils can vary widely depending on their composition and usage. Generally, they can yield between 60-80% of refined oil.

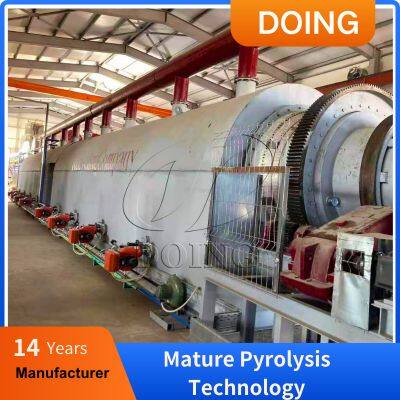

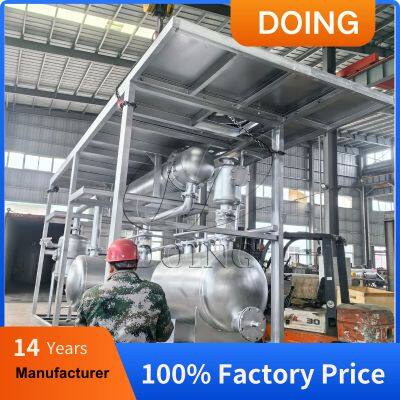

Waste oil distillation devices offer a viable solution for recycling various types of waste oils, transforming them into reusable products with considerable oil yield. DOING GROUP designs two types of waste oil distillation device, one is the normal design waste oil distillation device using acid and alkali washingand the other one is the new design waste oil distillation device using patened catalysts and ceramic balls. If you want to improve the quality of waste oil, welcome to contact us for more details.

��Whatsapp us: 008613526692320

��E-mail: oilmachine@wastetireoil.com

http://www.wasteoiltodieseloil.com

Recently Posted

-

Complete Guide: How to Launch a Profitable Waste Tire Pyrolysis Plant

January 13, 2026With the growing demand for effective and eco-friendly waste tire disposal solutions, waste tire pyrolysis plants have gained incr Read More

Read More -

Batch-Type Plastic Pyrolysis Equipment for Sale

January 5, 2026In the quest to manage and repurpose plastic waste, batch-type plastic pyrolysis equipment emerges as a groundbreaking solution. T Read More

Read More